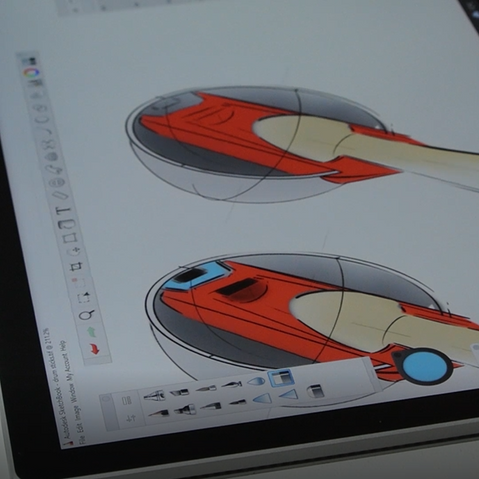

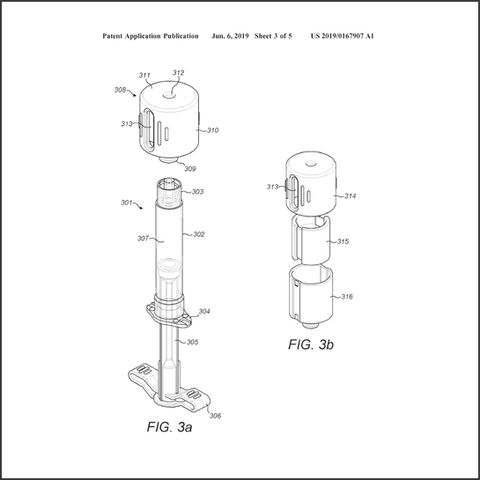

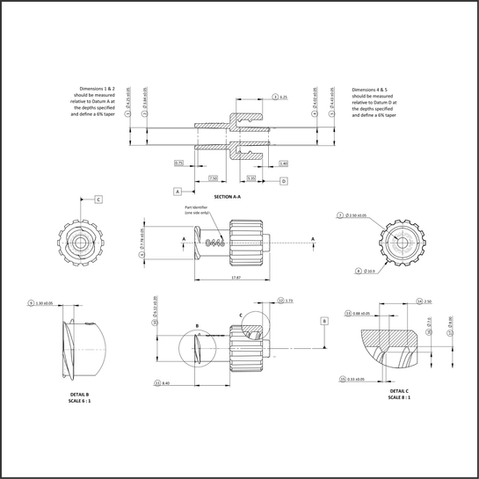

CAPABILITIES

ABOUT

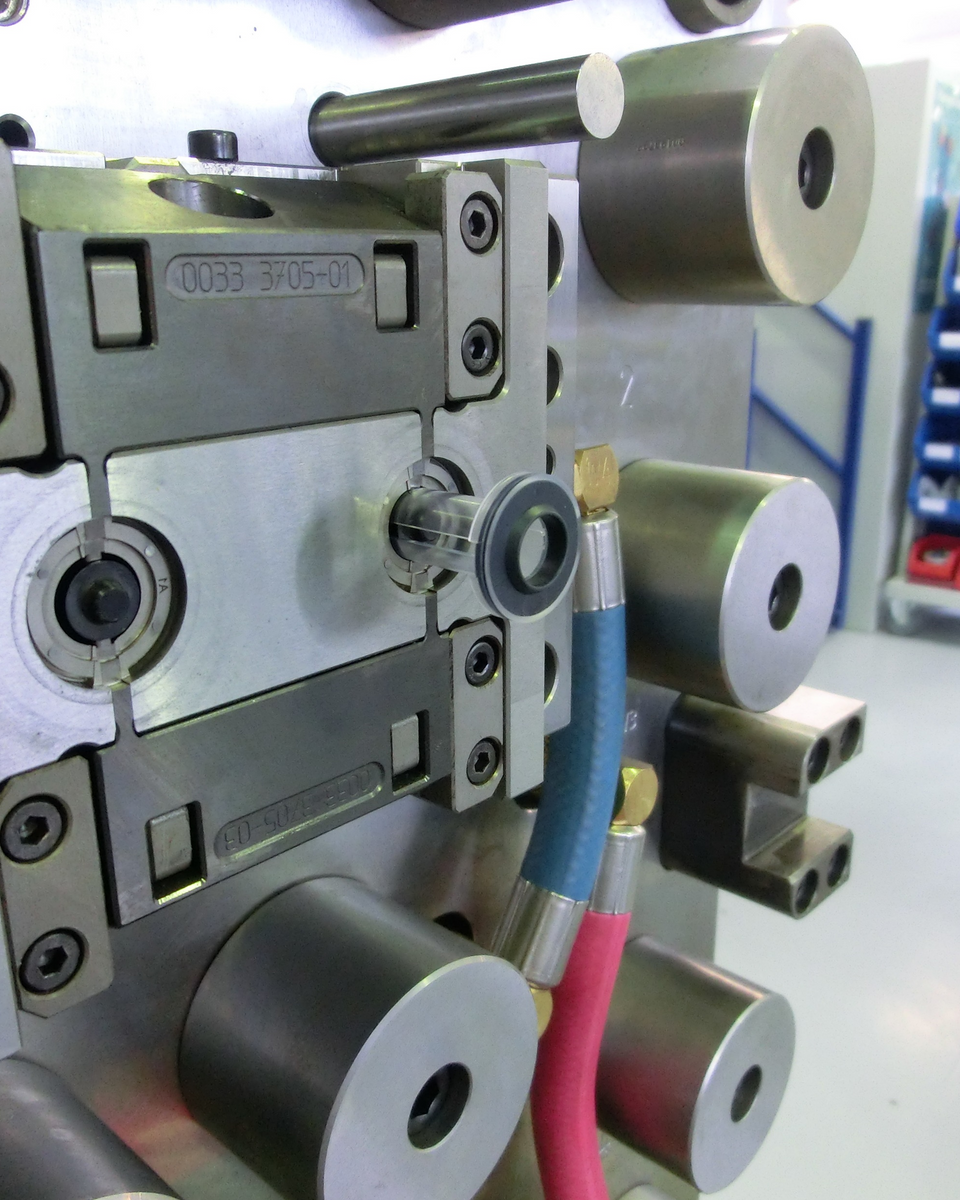

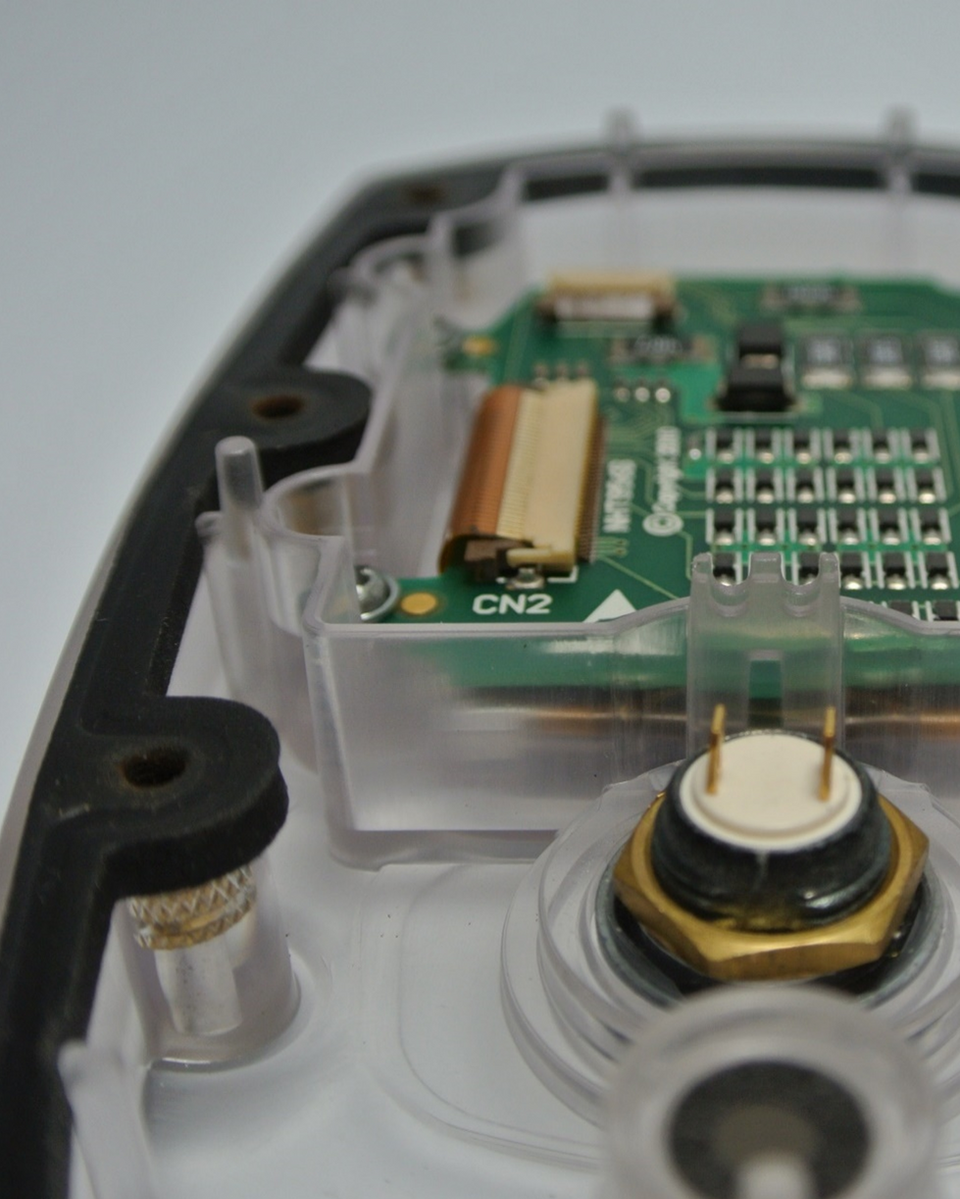

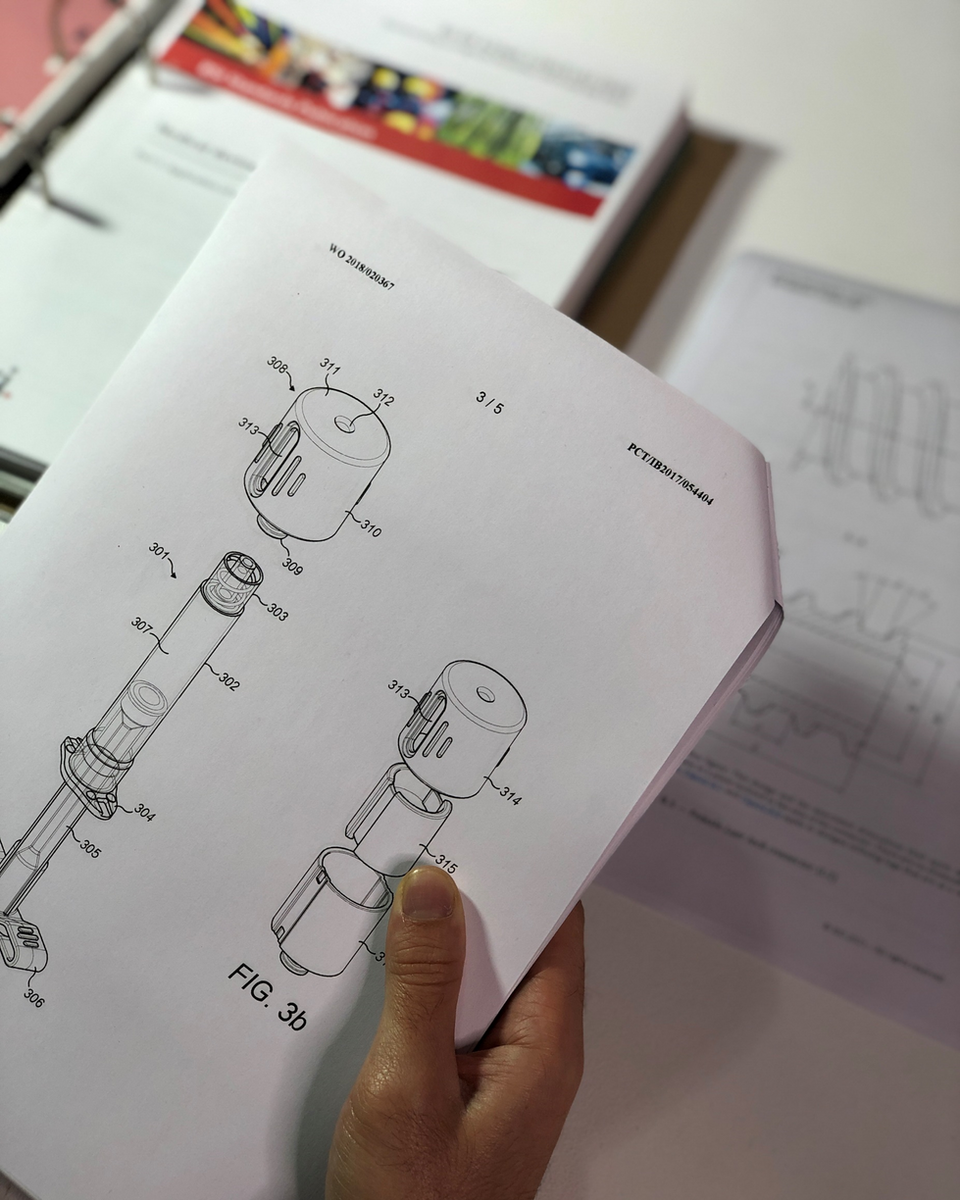

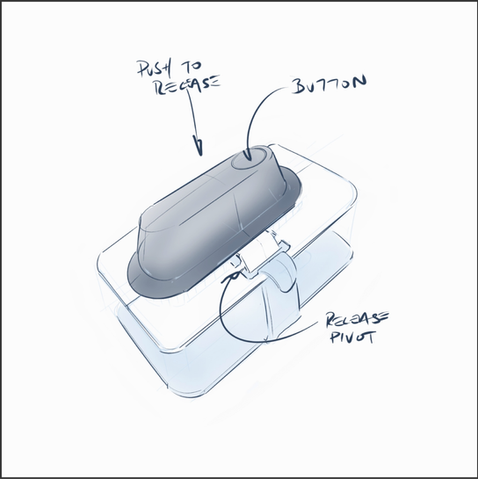

Established in 2012, D Squared Product Development is a Liverpool-based SME that offers product development, design and engineering consultancy services, to clients across the consumer, medical and industrial sectors.

We enable individuals, universities, hospitals, and new technology start-ups to bring innovative new products and medical devices to market, as well as supporting established manufacturers looking to improve on their existing ranges, and/or outsource elements of their development process.

With experience in both consultancy and manufacturing environments, our multidisciplinary team has gained extensive knowledge of the entire development process, from early-stage research and development activities to industrialisation and production scale-up.

Located in the UK but serving clients internationally, we are happy to offer a free consultation to discuss your development requirements further.

2012

Year Established

45

Projects Completed

52

Patents

Granted

3

Awards Won

SELECTED WORK

OTHER

CLIENTS &

COLLABORATORS

CONTACT

Get in touch

Contact Us

Locate us

D Squared Product Development

25 Carlton Street

Liverpool

L3 7ED

Employment

Not currently recruiting